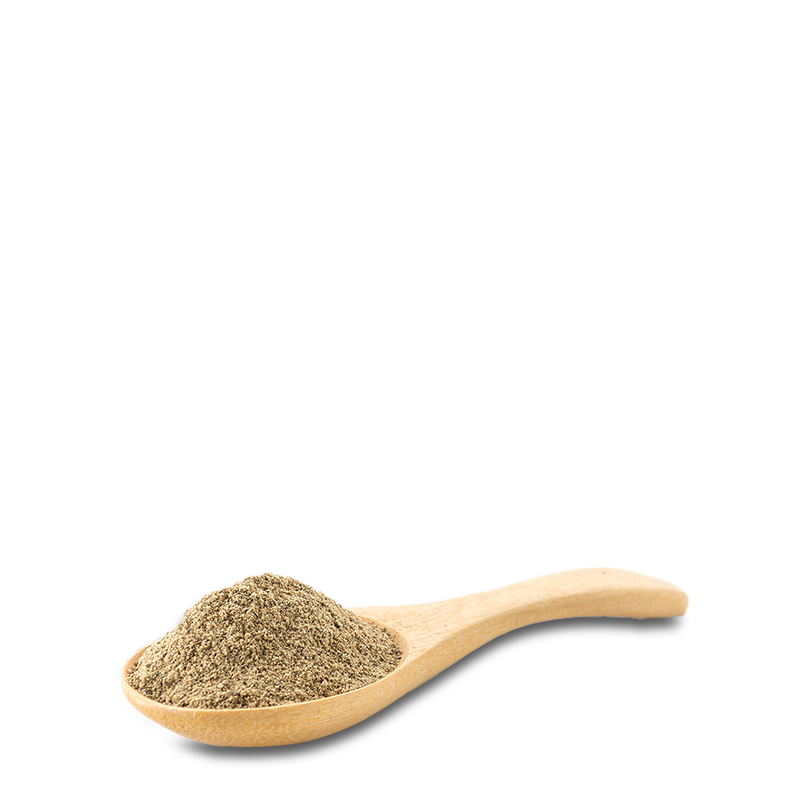

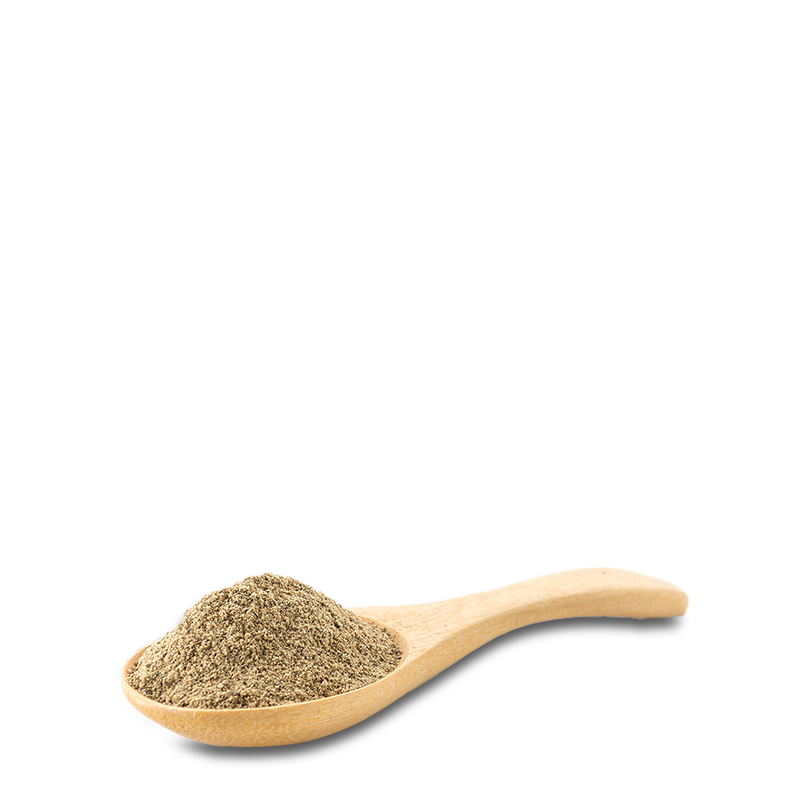

Spray Dried

Spray-dried flavors are often the answer for

manufacturers who need food flavoring with a long shelf life.To create a spray-dried flavor, we start with a concentrated liquid base and add it to emulsifiers to create an emulsion. This emulsion is then put through a spray drier unit to eliminate the water so that the end product is a fine, encapsulated powder. Our spray-drying process prevents food flavorings from reacting with other product ingredients, improves heat and oxidation resistance, and protects our flavors’ integrity and consistency.

This process accounts for about 80 percent of all encapsulated spray flavors sold in the U.S. today. And our flavor chemists are very good at getting it right.

Our Capabilities

Mother Murphy’s flavor chemists are experienced in the varied encapsulation techniques that can be used to create spray-dried flavors. It’s their knowledge of nuances that allows us to offer more options for spray-dried flavors than many of our competitors.